Why use DyeSub Photo Printers?

Dye Sublimation is a technology that is used in all Dye Sub Photo Printers (otherwise known as Dye Sublimation Photo Printers or D2T2). This technology has been around for many years and is very popular for high quality, high speed, durable photo prints.

Dye Sub Photo Printers allow you to produce high quality, photo prints at a fixed, low cost using this technology.

The Main Benefits of Dye Sub Photo Printers

- Durability of Dye Sub Photos:

There is no smudging, running, or blotching because your prints are dry and ready to touch as soon as they leave the printer. - Quality of Print:

The quality of a print from a Dye Sub is very high due to the fact it is a continuous tone device unlike an inkjet printer - Cost Effective:

Calculating the cost of prints is very simple with a Dye Sub compared to an Inkjet printer - Print Speed

Most Dye Sub photo printers can print a photo in under 12 seconds! Inkjet printers can only achieve speeds like this if printing in draft quality. - Print Resolution:

Dye Sub Printers usually print at 300dpi which matches conventional printing methods. Inkjet printers have to print at a much higher resolution to obtain better quality images. Find out the truth about print resolution.

- No Mess

There are no ‘ink’ cartridges with Dye Sub Photo printers, just an ink ribbon which doesn’t cause any mess whatsoever. - No Hassle

When media is loaded in a Dye Sub printer you can print many hundreds of prints without having to load paper each time. There is also a given number of prints with each box of media so you’ll have no ink cartridges that will run out part way through a print run and waste ink and paper. Each print on a dye sub is perfect. - Space Saving

Given that the media is usually inside the printer you don’t have paper in a paper tray gathering dust and taking up room. - Flexible Print Sizes

Most Dye Sub Media can print multiple sizes from one media type.

Dye Sublimation is a technology that is used in all Dye Sub Photo Printers (otherwise known as Dye Sublimation Photo Printers or D2T2). This technology has been around for many years and is very popular for high quality, high speed, durable photo prints.

Superb Quality

Dye-sub printers can achieve very consistent and accurate color reproduction, making them popular in applications such as professional photography, graphic design, and textile printing. They can reproduce colors more faithfully than some inkjet printers, which may struggle with color accuracy.

Various Print Sizes

The print size is determined by the printer and media used. Printers usually use a roll of paper and a special ribbon. The maximim size a Dye Sub printer can print (depending on the model) is 12″x8″. Some Photo Printers that use a 6 inch roll can print Panoramic prints upto 6″x20″.

Dye Sub Photo Printers are primarily photo printers so the media they use is primarility available in standard print sizes. The printers can usually print various sizes.

Glossy or Matt?

Dye-sublimation photo printers typically produce prints with a glossy finish by default. The glossy finish is a result of the dye-sublimation process, where the dyes are vaporized and then solidified on the printing medium, such as photo paper or transfer paper. This process naturally creates a glossy surface. However, if you prefer a matte finish for your prints, this can achieve on most Dye Sub Printers by producing a fine pattern in the top level UV coat which gives the impression of a matt print.

Can Dye Subs Print Black and White?

Dye-sublimation printers are versatile and can produce high-quality black and white prints suitable for various applications, including photography, graphic design, and art reproduction. The key is to prepare your image correctly and adjust the printer settings to achieve the desired black and white output.

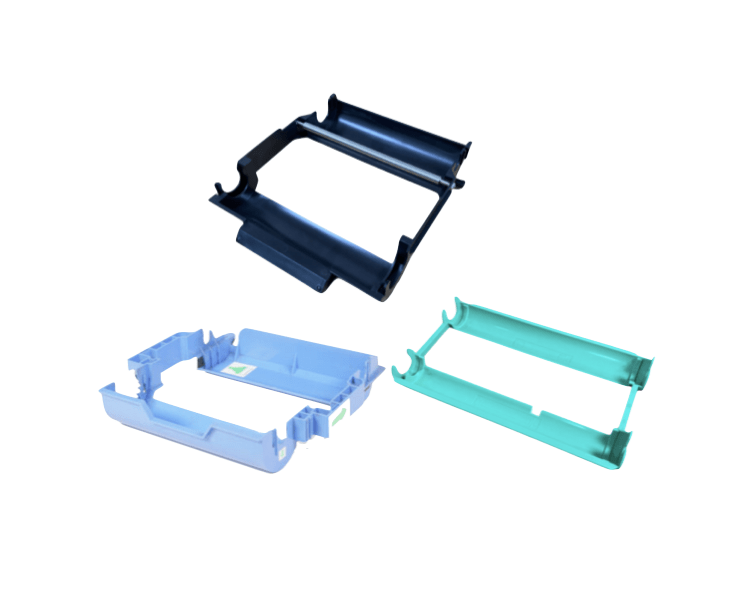

Photo Print Media

Dye Sublimation Photo Print Media is available in variety of print sizes, it is easy to load into your Photo Printer and the cost per print… [Read More]

The Tech Stuff…

The print head in Dye Sub Photo printers is capable of producing 256 levels of each colour (cyan, magenta, yellow), and is able to create a total of 16.77 million true colours by combining these three primary colours. Using a special over-coating layer, the dye layers are sealed into the paper and the image is protected against UV light, fingerprints, and even water.

Photographic Prints are made using this Dye Sublimation printing technique that diffuses dye onto paper. This dye comes in the form of a ribbon, which is converted into a diffused gas when heat is applied, and is absorbed by a special receiving layer on the paper.

The print head heats very accurately to varying temperatures, creating different shades of colour depending on the amount of heat that is produced.